BACKGROUND

Industrial biopharmaceutical cell culture necessitates an expensive and risky scale-up process to get production scale volumes in order to manufacture proteins and other biopharmaceutical products. Traditional stirred single-use bioreactor bags can only scale to a five-fold maximum, but scaling for production requires several thousand fold increases. For industrial production, a complex seed train of multiple disposable bags with associated equipment are needed. These production scaling practices depend on highly trained personnel working in aseptic conditions on highly specialized equipment that occupies large amounts of space. There is an industry-wide need for a more effective single-use bioreactor to reduce costs and waste associated with production of biopharmaceuticals.

SUMMARY OF TECHNOLOGY

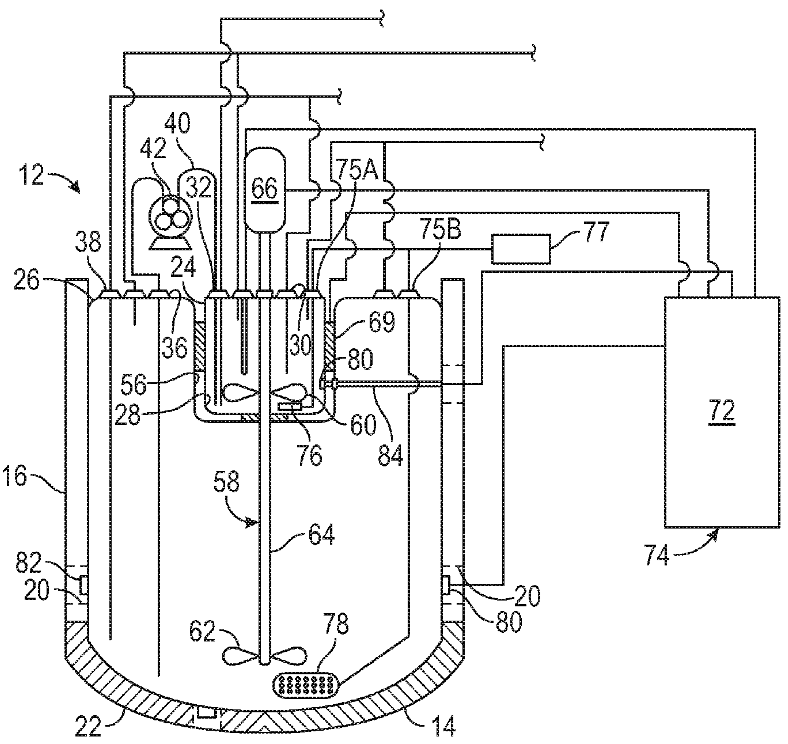

OSU researchers have developed a novel multi-chamber, disposable, bioreactor which addresses the problems inherent with scaling mammalian cell culture to production levels. The disposable bioreactor bag is composed of a large outer bag surrounding one or more smaller inner bags (see figure). A single control unit and support structure is needed for the whole unit, cutting the amount of equipment and space needed for output. The bioreactor allows for up to 1000-fold volume scalability, bringing a single bioreactor into production scale. This new technology eliminates the risk of contamination, protecting batches from being compromised, as well as reducing the amount of labor needed to create a product.

POTENTIAL AREAS OF APPLICATION

- More cost-effective biomanufacturing of mammalian cells.

MAIN ADVANTAGES

- 50-1000-fold volume scalability (current stirred tank single-use bioreactors is ~5-fold)

- Greatly reduces risk of cross-contamination by removing need for intermediate bags, protecting against lost revenue (~$1.2M per 1000L of antibodies)

- Significant savings on equipment and labor costs (>$200,000 per intermediate bag eliminated in equipment cost alone)

- Reduces factory footprint

COMMERCIAL OPPORTUNITY

Driven by loss of patent protection on existing protein pharmaceuticals, the current single-use bioreactor market of $3.4 billion is projected to grow to $8.8 billion by 2026, a CAGR of 21.1%. This presents a significant opportunity for small biopharmaceutical manufacturers that will primarily use single-use bioreactors. We are searching for industry partners to help commercialize this patent-pending technology.

STATE OF DEVELOPMENT

A product prototype has been completed and is available for demonstration.

LICENSING CONTACT

Please contact Russell Hopper russell.hopper@okstate.edu for more information.