BACKGROUND

In many applications such as in the aerospace domain, multifunctional structures that provide structural integrity and conformity, and aerodynamic functions, but in addition also acoustic noise mitigation as well as thermal management functions are desired. Addressing low-frequency (<~1000 Hz) acoustic noise mitigation using lightweight, compact, extreme environment compatible liner structures is particularly challenging. Further, it is desirable that the acoustic absorption bandwidth for such liners has a broadband performance encompassing these hitherto unaddressed low-frequency dominant content. In this context, a combination of materials, design configurations, and a numerical optimization methodology is proposed to deliver the functions for aerospace applications

SUMMARY OF TECHNOLOGY

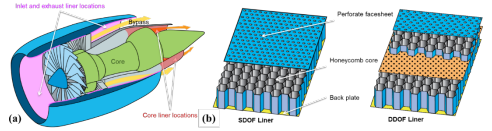

The proposed solution melds acoustically non-rigid elements with thermally functionalized bulk absorbers in tailored architectures using a ZKTL-based optimization process. Proof-of-concept evaluations have verified the acoustic performance feasibility of mechanical design for the proposed approach. Figure 1(a) shows the acoustic liner treatment areas within a turbofan engine. Liners are applied both in the nacelles and by-pass ducts, where the temperatures and pressures experienced are relatively lower as well as within the engine’s core with much higher temperatures and pressures. In both locations, the amount of space (volume) available for the liner treatment is very limited (1-2” depth at most). With the move to higher by-pass ratios for more efficient engines, the fan diameters have increased dramatically. This results in lower blade passage frequencies and consequently more dominant low-frequency (<~1000 Hz) content in the acoustic noise spectrum. Conventional single and double degree of freedom liners (Figure 1b) cannot address these low-frequency components without incurring impractical weight and volume penalties. This motivates the investigation and implementation of new solutions to mitigate these hitherto unaddressed low-frequency components considering emergent, more stringent regulations for sustainable global aviation.

Figure 1(a): Schematic depiction of a turbofan engines with locations of inlet/exhaust and core acoustic liners; (b) Conventional perforate over honeycomb-core single and double degree of freedom acoustic liners.

POTENTIAL AREAS OF APPLICATION

- Aerospace and aircraft industry

- HVAC systems manufacturing

MAIN ADVANTAGES

- No competition working with low frequencies (<~1000 Hz).

STAGE OF DEVELOPMENT

- There is a Proof of Concept for this technology.

CONTACT: Please contact Russell Hopper russell.hopper@okstate.edu for more information.